- Planning of cyclic recurring maintenance tasks and revision tasks at freely defineable intervals

- Acquisition of alerts with optional, automatic message of freely defineable persons or groups via messaging system, e-mail or SMS

- Automatic or manual generated maintenance tasks with allocation of responsible technician or use group, necessary spare parts, any document, predefined working times, descriptions and type of maintenance

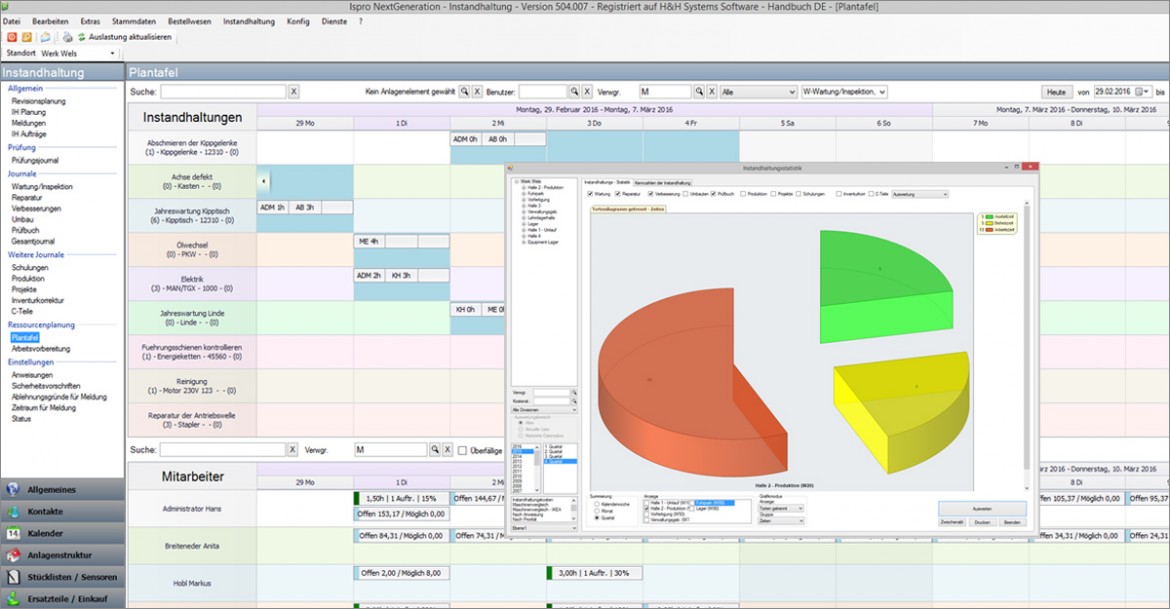

- Release workflow

- Dynamic adaption of the maintenance cycles

- Automatic allocation of used spare parts to bill of material

- Frame Task with definable subtasks (working steps) - For long lasting maintenances or revisions with so many partial tasks as needed

- Scan2Task - maintenance tasks in paper form with automated actions during scanning the filled in forms

- Different maintenance journals for evaluations or direct acquisition of already finished maintenance activities (inspection, maintenance, improvement, reparation, legal compliance, production, reconstruction, project)

- Automatic calculation of working time, reparation- and downtime

- Allocation of maintenance instructions, damage pictures and causes for alerts

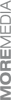

- Calender/Time management: structured calendar view over all (or selected) maintenance tasks with the possibility to edit the tasks directly

- Employee evaluation to type, cost centres and plant elements

- Interactive gantt chart for temporal scheduling of the maintenance tasks including resource utilisation chart

- Operating schedule/Resource planning: Operative maintenance planning with drag & drop for work scheduling

- Sensors for condition based maintenance: Definition of any number of checkpoints/measured values for each plant element. Data can be entered manually or transferred via an OPC interface.

Maintenance

Our powerful and user friendly Maintenance Management supports you in planning, administration and examination of your maintenance tasks. It covers all important fields like inspection, maintenance, reparation or legally prescribed inspections.

powerful complete system

Show all modules